Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Ball screw by the screw, nut, steel ball, reverse device, or dust collector composition, is the most commonly used transmission mechanism for tool machinery and precision machinery. Its main function is to convert the rotary motion into linear motion or convert the torque into axial recurrent force, with both high precision, reversible, and high-efficiency characteristics. Due to its small frictional resistance, the ball screw is widely used in a variety of industrial equipment and precision instruments.

Type selection

Ballscrews, according to the ball of the cycle can be divided into Floating Deflector, Cover Plate Deflector, End Cover Deflector, Intubated Deflector, and Cutting Type Deflector. These three recycling methods have each characteristics.

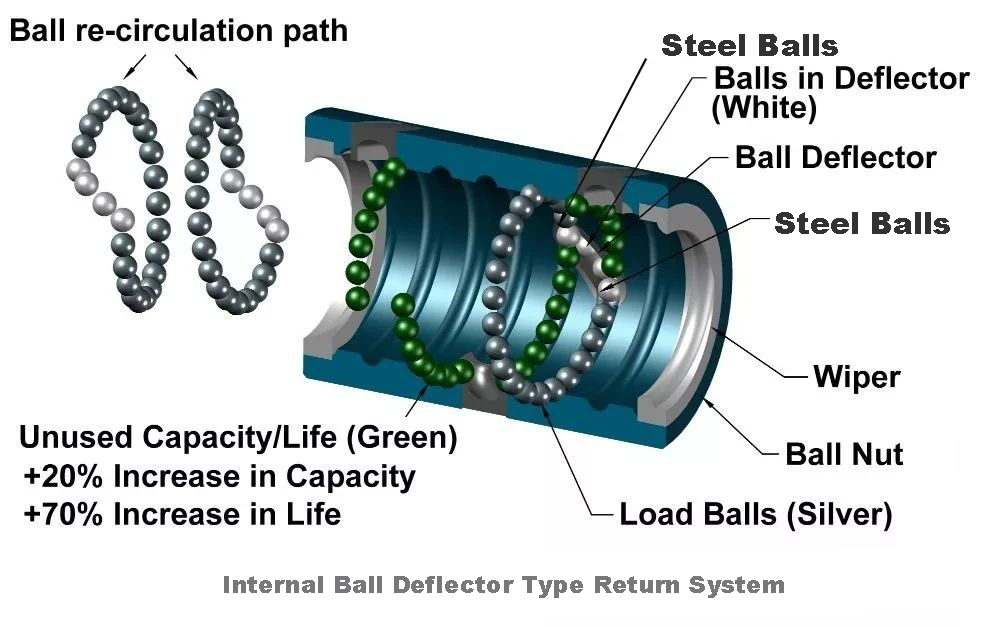

1. Floating Deflector

Floating Deflector return is the most basic and widely used, with the help of path on the role of the bead groove, forcing the ball rolling along the raceway, over the screw thread raceway after the tooth tip, back to the initial raceway, formed a circular ball chain, suitable for all kinds of diameter and nut style.

2. Cover Plate Deflector

Nut with return plate, suitable for large lead ball screw, large load, and low in cost.

3. End Cover Deflector

Refers to how the steel ball rolls along the groove between the screw shaft and the nut, passes through the through hole on the nut through the path installed on the end cover backer at both ends of the nut, and returns to the original position. It is suitable for the design of high-speed light load and low noise.

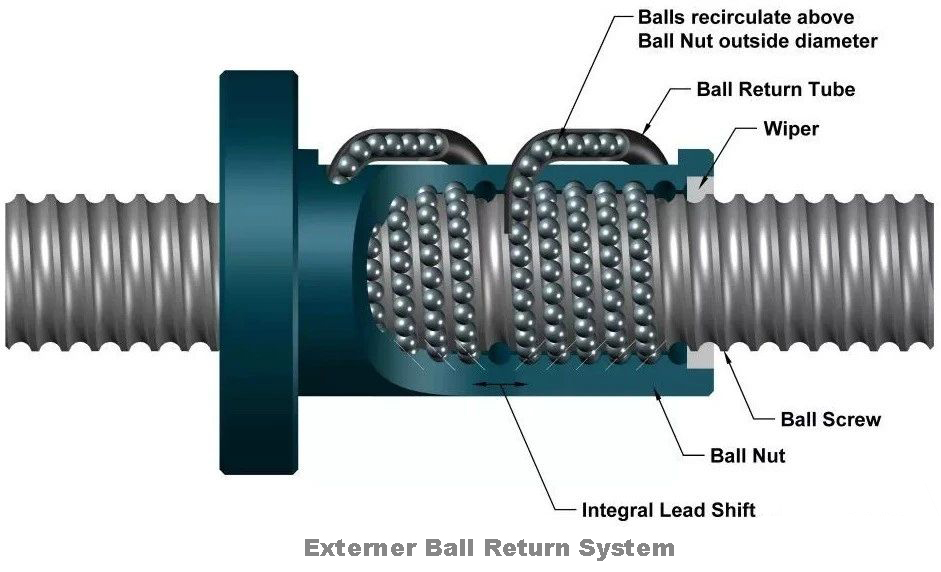

4. Intubated Deflector

The return tube recirculation type is an evolution from the internal deflector. To guide the balls into and out of the elbow tube utilize a tongue bevel at the end of the elbow tube inserted into the hole or other form of bead stopper.

5. Cutting Type Deflector

The cutting type deflector has the advantages of small space and high load capacity, while with higher difficulty. So this type is proper for some special situations.

October 16, 2024

October 14, 2024

इस आपूर्तिकर्ता को ईमेल

October 16, 2024

October 14, 2024

October 18, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.